EMS(Electronic Manufacturing Services)

To support your flexible response against a changing market, Meiko offers total solution services that can centralize entire processes outsourcing from pattern design to manufacture, components procurement, SMT, inspection and delivery. (Matching factory: Vietnam Plant)

Meiko Electronics EMS business features

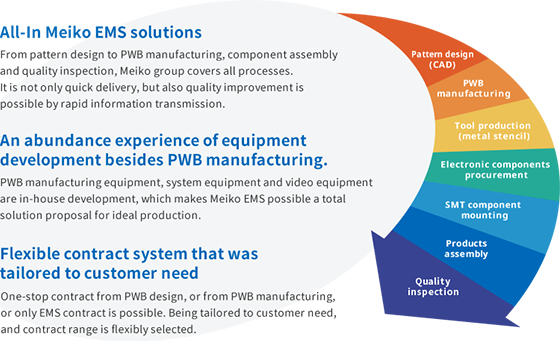

All-In Meiko EMS solutions

From pattern design to PWB manufacturing, component assembly and quality inspection, Meiko group covers all processes. It is not only quick delivery, but also quality improvement is possible by rapid information transmission.

An abundance experience of equipment development besides PWB manufacturing.

PWB manufacturing equipment, system equipment and video equipment are in-house development, which makes Meiko EMS possible a total solution proposal for ideal production.

Flexible contract system that was tailored to customer need

One-stop contract from PWB design, or from PWB manufacturing, or only EMS contract is possible. Being tailored to customer need, and contract range is flexibly selected.

EMS order result

EMS contract from global top companies.

For example, panel module, office equipment, earphones, storage, vehicle sensor, vehicle lighting etc.

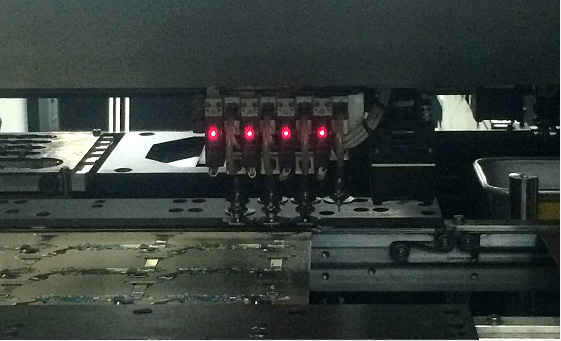

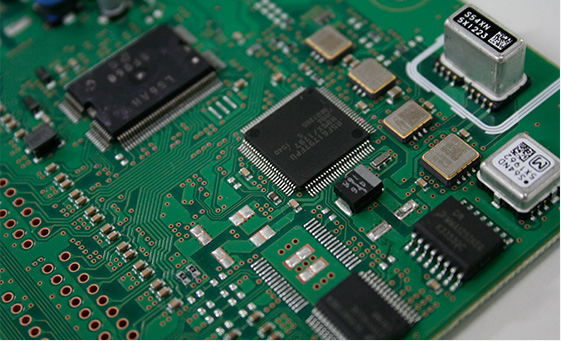

Surface Mount Technology

State-of-the-art equipment for SMT.

- Solder cream printer

Fine-pitch printing by house made high-precision metal stencil. - Mounter

Minimum Chip(0402), narrow gap, WCSP(pitch 200um). - AOI

In-Line complete quality assurance for Key processes(solder print, SMT, soldering) - Reflow equipment

Lead-free (Nitrogen less than 1,000ppm possible ) - Cleaning equipment

Flux cleansing(direct path methods), ultrasonic aquatic cleansing - ACF connection,ACP connection, X-ray inspection equipment(CT scan support)

Plant's utilities that was enhanced with clean environment

- Surface Mounting and assembly in a clean room condition. (class 10,000)

- Optimum temperature and humidity environment(20-28℃/40-70%) for electronic packaging

- Electrostatic discharge of factory area(100 V or less)

Integrated Surface Mount facilities and production system.

- Packaging lines basic equipment configuration and operation system is unified.

Plenty of SMT and product assembly experience.

- Widely covered assembly technology from discrete device assembly to module assembly.