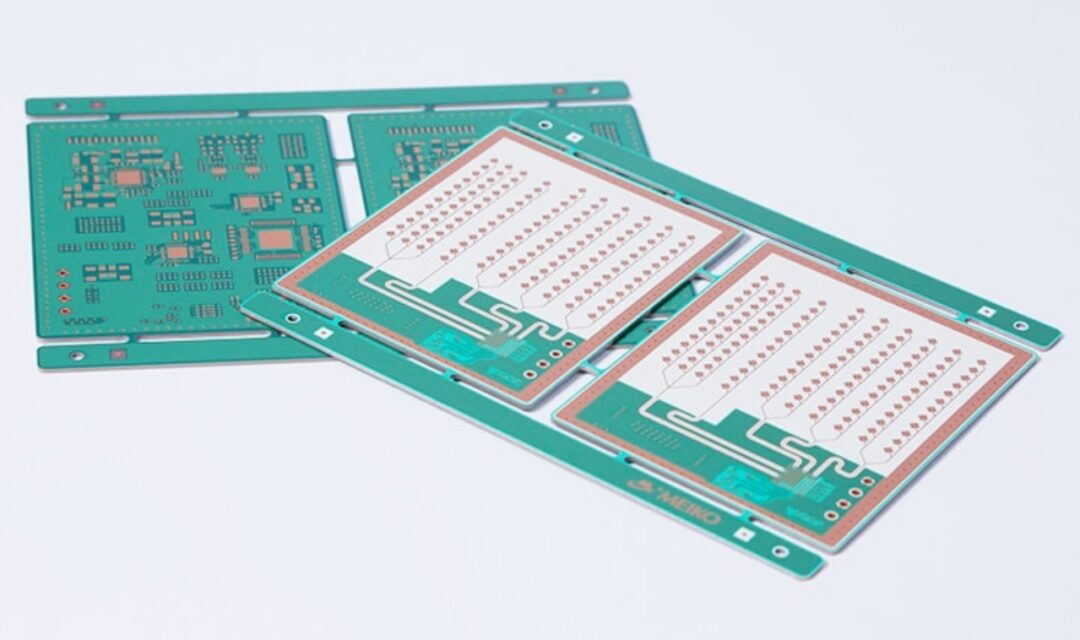

Millimeter Wave Radar PCBs

Meiko has considered various high-frequency compatible materials and developed circuit boards for automotive millimeter-wave radar (ADAS). We provide hybrid structure circuit boards that use general circuit board materials except for the surface layer that requires high-frequency compatibility. This allows for lower costs, multi-layer compatibility, and improved wiring flexibility.

High frequency compatible PCBs

01

Features of the Millimeter Wave Radar PCBs

- Combining high-frequency materials with general materials to reduce costs

- High-precision circuit formation using the MSAP method

02

Main uses

-

Automotive millimeter wave radar (ADAS)

-

5G base station antenna

-

Monitoring Sensors

Contact About the productInquiry

In addition to major corporate clients, we also serve universities, research institutes,

We also accept consultations from venture companies.

We also accept one-off orders from design companies and parts trading companies,

Please feel free to contact us for technical advice.