MEIKO

MEIKO INTRODUCTION

We will introduce our business briefly

so that people unfamiliar with Meiko can understand it easily.

Chapter 1. Around you

A LOT of MEIKO

around you.

Meiko’s PCBs are used in electronic devices around you.

In the areas of automobiles, telecommunications,

industrial devices and amusement/

home appliances, Meiko has manufactured

a wide variety of PCBs based on various

customer needs to contribute

to everyone’s life.

-

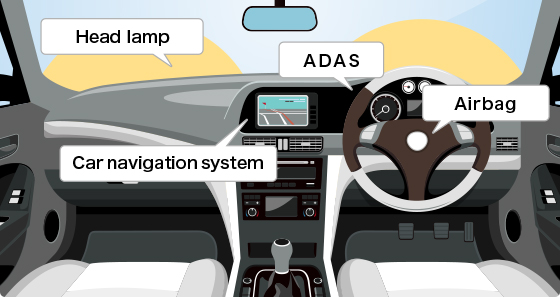

Automobile

-

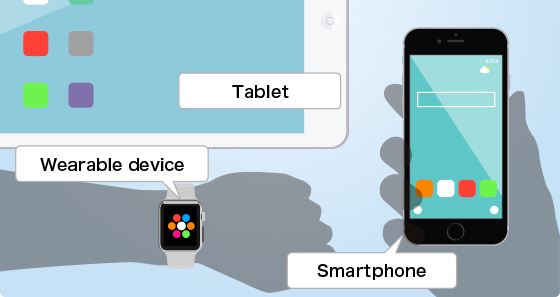

Telecommunications

-

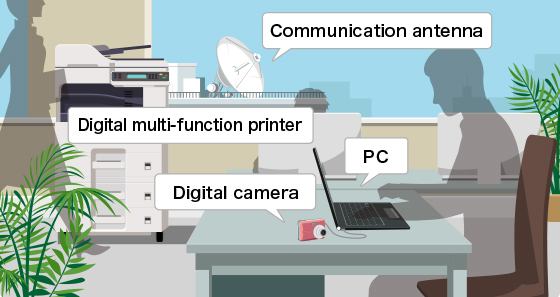

Industrial devices

-

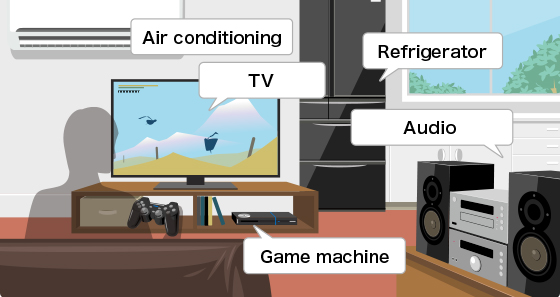

Amusement/home appliances

Chapter 2. History of Meiko

-

The 1970s

Foundation of growth built by the arcade game boom

In October 1974, current President & CEO Yuichiro Naya founded Meiko Denshi Kogyo Co., Ltd. (currently Meiko Electronics Co., Ltd.).

Naya started pattern design and manufacture of through-hole PCBs

in a modified cabin of about 33m2 in his yard.

He did all drilling work manually without NC machines, and outsourced plating work.

In 1979, following the big boom of a shooting game called Space Invaders,

Meiko rode this big wave and started growing rapidly by providing gaming PCBs.

-

The 1980s

10th anniversary as a turning point

New products were actively developed based on novel ideas such as multi-video processors.

In 1982, Yamagata Meiko Denshi Co., Ltd. (currently Yamagata Meiko Electronics Co., Ltd.) was founded. In 1984, a site for the Fukushima factory was acquired. In 1985, Meiko celebrated its 10th anniversary without experiencing any setbacks.

In the same year, however, Meiko recorded a financial deficit for the first time due to the rapid yen appreciation caused by the Plaza Accord.

Meiko overcame this crisis by taking orders focusing on potential of automobile-related products.

-

The 1990s

From Meiko Denshi Kogyo Co., Ltd. to Meiko Electronics Co., Ltd.

Fukushima Factory started operations which had been postponed due to the rapid change in business conditions.

In 1991, the company name was changed to the current one, Meiko Electronics Co., Ltd.

In the same year, due to the continuous appreciation of the yen caused by the burst of bubble economy, the industry as a whole started shifting from work of craftsmanship

to a device industry that requires a large amount of capital investment.

In order to catch up with this trend, Meiko prepared mass-production systems at its Yamagata and Fukushima factories,

and decided to operate in China to achieve stable management not affected by exchange fluctuations.

-

The 2000s

Active expansion overseas

In December 2000, Meiko listed its shares on the former JASDAQ Securities Exchange.

In 2001, Meiko expanded overseas earlier than its competitors and completed the Guangzhou factory in China.

In 2004, a mass-production base was acquired for highly multi-layer PCBs. The next year, the former Miyagi Meiko was founded

and a production base was acquired for HDI PCBs. In 2006, Wuhan factory in China was completed.

In 2008, Meiko achieved financial surplus

despite the financial crisis caused by the subprime mortgage problem in the U.S.

In 2009, the EMS factory in Vietnam started operations.

In the same year, Meiko started its partnership with Germany-based Schweizer Electronic.

-

The 2010s

Overcome the Great East Japan Earthquake

In the Great East Japan Earthquake in 2011, the Miyagi factory was damaged by the tsunami,

and the Fukushima factory was forced to suspend its operations due to the nuclear power plant accident.

In the face of this difficulty, Meiko continued every effort to restart operations,

and completed the recovery of the Fukushima factory in 2011 and the Ishinomaki branch factory (the former Miyagi factory) in 2013.

Overseas, Meiko established a system to meet expanding demand for PCBs for

smartphones by establishing two new mass-production factories in Vietnam.

In 2015, Meiko started the solar power generation business by establishing

Meiko Solar Park Fukushima, a solar power plant on the premises of the Fukushima factory.

Chapter 3. Technological strengths of Meiko

Meiko has wide-ranging technological strengths and a solid track record

Technologies to Support Safety Control

While a very stringent quality standard has already been defined for PCBs used in passenger vehicles, Meiko has reliable technologies and has built trust since the 1980s based on our experience in transactions with automakers. Meiko produces PCBs used for vehicle’s ADAS (Advanced Driver Assistance System). ADAS is a system to detect the risk of an accident in advance and avoid it.

Technologies to Support Telecommunications

PCBs developed by Meiko have features compatible with high-speed lines, which are indispensable for realization of the next-generation communication society. In the next-generation communication society, the speed at which information can be exchanged will be important. Meiko also produces high-density-wiring and high-spec PCBs for smartphones and other communication devices, and PCBs used for their base stations, which means Meiko has the ability to support the next-generation infrastructure.

The era of IoT is coming.

In preparation for the next generation, Meiko will

Chapter 4. CSR activities of Meiko

Contribute to the future of the region and town along with customers

Provision of educational PCBs to RICOH Future House

Meiko provides educational materials to RICOH Future House, a new project by Ricoh Co., Ltd. RICOH Future House is a place to create business for the future together with the region and town based on the design concept of a house.

The 3rd floor is a facility for elementary and junior high school students to experience and learn about science and technology to develop future scientists and engineers. In this learning facility, workshops of electrical work to make a robot, for example, are held using PCBs from Meiko. As part of its contribution to the region and town, Meiko specially provides PCBs free of charge.

Contribution to the local community by lowering environmental burdens

Solar power generation started in Meiko Solar Park Fukushima

For the purpose of the restoration of the Fukushima factory after the Great East Japan Earthquake and the nuclear power plant accident, as well as contributing to the local community through lowering environmental burdens by introducing renewable energy, Meiko built a solar power plant on the premises of the Fukushima factory and started power generation in June 2015.

It is planned that the operation of this power plant will assist the renewable energy promotion activities carried out by Fukushima Prefecture and Hirono Town after the Great East Japan Earthquake, as well as the global environment and the formation of a sustainable society.

Chapter 5. Testimonials

Meiko has been recognized in a wide variety of areas by meeting customer needs.

-

Panasonic AIS selected us as the Best Suppliers

Our Guangzhou and Wuhan plants were selected by Panasonic AIS as the Best Suppliers for their quality improvement measures in FY2015.

-

Meiko won the Award of Excellence

in the In-Process Failure 3 Zero Activities from Toyota Motor Corporation.Meiko won the Award of Excellence for its achievement of the quality goal by making active effort for zero failures, zero outflows and zero recurrences in the production process to ensure quality.

-

THE BEST PARTNER IN 2015 award

from Samsung Electronics VietnamOur Vietnam plant was ranked first in the environment & safety section among Samsung Electronics Vietnam’s 60 partners and won the Best Partner Award.

-

Fuji Xerox selected us as a Premier Partner for six consecutive years

In the Procurement Partners’ Forum 2016 of Fuji Xerox Co., Ltd., we were selected as the premier partner. We are the only PCB manufacturer selected.