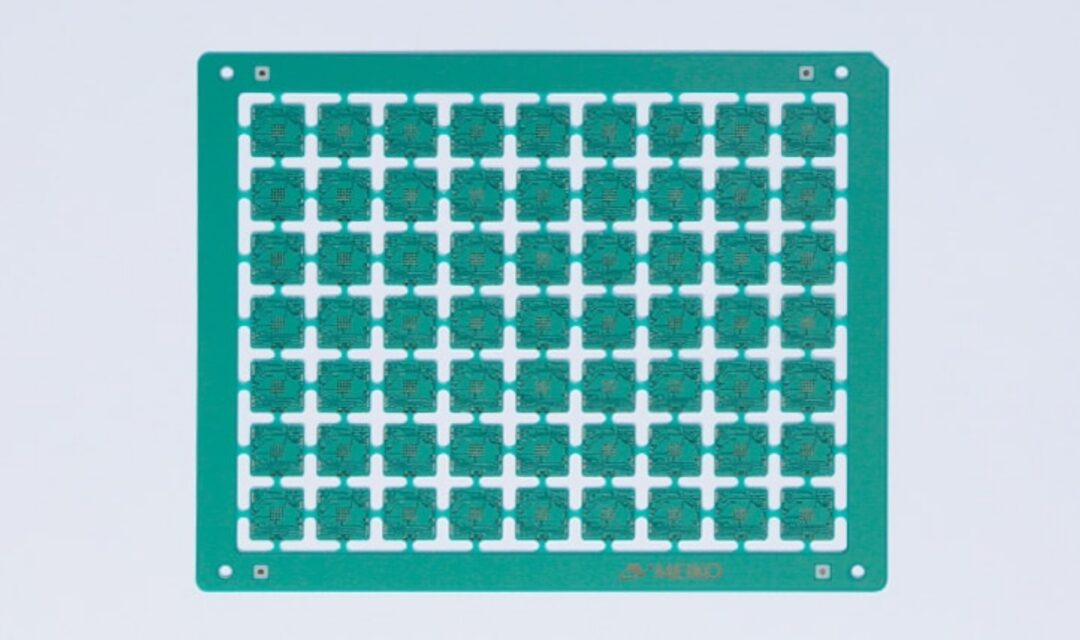

Embedded Device PCBs

A board for flexible wiring and ultra-compactness. As the number of passive components mounted on small mobile devices increases, there is a demand for higher density component mounting. However, as there is a limit to the surface mounting area that can be achieved with conventional surface mounting technology (two-dimensional mounting arrangement), three-dimensional mounting arrangement using "component-embedded boards" has been proposed. Meiko has been researching and developing "component-embedded boards" for many years and has an excellent track record.

Features of Embedded Device PCBss

- Miniaturization and high integration of products that mount chip components inside a substrate

- Reduced wiring length reduces inductance and noise

Main uses

-

Communication Module

-

Wearable devices

-

Camera module

Contact About the productInquiry

In addition to major corporate clients, we also serve universities, research institutes,

We also accept consultations from venture companies.

We also accept one-off orders from design companies and parts trading companies,

Please feel free to contact us for technical advice.